| By Ashvin Patil, Founder and Director, Biofuels Junction

The clean energy transition towards biofuels is rapidly picking up in India and is seen as one of the biggest markets worldwide driven by the push by the Indian government in making the switch to renewable and environmentally friendly energy sources.

The paradigm shift towards carbon neutrality and broader net-zero targets is driving a fundamental transformation in how Indian industries approach their operations and processes. Leading Indian manufacturers are increasingly shifting towards biofuels especially biomass briquette and pellets made from farm waste, over furnace oil and coal for several reasons, driven by environmental, economic, and policy driven factors.

India generates around 500 million tonne of agri residue every year and of which almost 200 million tonne is destroyed or burnt without any productive use. This in value terms is almost INR 50,000 crore worth of business. Indian start-ups in the biofuels space are looking at tapping this opportunity with various solutions ranging from agriculture residue collection to supplier development to large scale aggregation and supply chain consulting to bridge this gap across the entire value chain from the agricultural farmer to the final energy creation by the manufacturer.

International Agreements and Commitments Government Policies and Incentives:

Air pollution in Indian cities has been a major concern for several years and continues to be a significant public health and environmental issue. In order to curb air pollution, in January this year, the central government’s Commission for Air Quality Management (CAQM), banned the use of coal and other unapproved fuels in industries in the Delhi- NCR region. Other populous Indian cities such as Mumbai, Pune, Chennai may also follow suit and bring in stricter regulations and efforts to mitigate air pollution.

According to the Centre of Science and Environment (CSE), till 2020, around 1.4 million tonnes of coal was being used by industries in six major industrial districts of Delhi-NCR: Panipat, Alwar, Sonipat, Ghaziabad, Faridabad and Gurgaon. Additionally, in its study the CSE flagged that, the coal usage in the small boilers of several small-scale textile industries of Panipat was one of the major air pollution contributors to the district in 2020.

The Indian government has implemented various policies and incentives to promote the use of biofuels. In 2015, India submitted its first Nationally Determined Contribution (NDC) to the United Nations Framework Convention on Climate Change (UNFCCC) pledging a 33-35 per cent reduction in the emissions intensity of its economy by 2030, compared to the 2005 levels.

These policies include blending mandates for biofuels in transportation fuels and financial incentives for biofuel producers. Such policy support encourages manufacturers to shift towards biofuels. India’s participation in international agreements such as the Paris Agreement and its commitment to reducing greenhouse gas emissions have prompted efforts to transition away from fossil fuels toward cleaner alternatives like biofuels.

Furthermore, the growing public awareness of environmental issues and changing consumer preferences for eco-friendly products have driven companies to adopt more sustainable practices, including the use of cleaner fuels like biofuels. Shifting to biofuels can significantly enhance a manufacturers reputation and appeal to environmentally conscious consumers. To promote solid biofuels supply and its ecosystem, the government has offered capital subsidies to rural entrepreneurs. We believe scope of this transition is much wider and long lasting, and the transition to biofuels will promote the Atmanirbhar Bharat and give an impetus to the Prime Minister Modi’s vision to achieve energy independence through clean technology by 2047.

Ashvin Patil, Founder and Director, Biofuels Junction

Waste Utilization and Circular Economy

Biomass briquettes are compressed blocks of biomass materials that are often used for heating in Industrial & Commercial applications. They are typically made from agricultural residues or wood waste and are produced by compressing biomass materials under high pressure without using any binding agents. Briquettes generally burn efficiently and easy & safe to store, handle and transport compared to loose biomass. The compression process results in a denser and more uniform fuel, which contributes to cleaner combustion.

Pellets are cylindrical or cylindrical-shaped biofuel particles made by compressing biomass materials into dense pellets. The production of pellets involves grinding and drying the biomass, then using heat to reduce moisture and pressure to create the compacted pellets. Pellets are highly standardized in size and shape, and due to smaller size higher surface area is available during combustion, ensuring consistent combustion and efficient heat release. Compact size makes pellet storage more space-efficient compared to other bulkier fuels and are also relatively easier to transport due to their standardized size and density.

Briquettes and pellets therefore contribute to sustainable energy practices by utilizing agricultural residues, wood waste, and other biomass materials that might otherwise be discarded. They offer efficient, cleaner-burning alternatives for various heating and energy needs, supporting the transition to renewable and environmentally friendly energy sources.

Biofuels are therefore a valuable component of the circular economy, contributing to renewable energy, emissions reduction, waste valorization, and the development of sustainable local economies. During the recent, G20 summit and the India Energy week in July, Hardeep S Puri, Minister of Petroleum & Natural Gas and Housing & Urban Affairs said that India will be one of the leading biofuel producer and consumer. India’s proposed Global Biofuel Alliance, seeks to accelerate sustainable biofuels deployment in support of the global energy transition.

Environmental benefits

There are several environmental benefits of switching to biofuels. India faces significant air quality and environmental challenges due to the burning of fossil fuels like coal and furnace oil. Biofuels are much more environmentally friendly compared to traditional fossil fuels like coal and diesel and other crude derivatives such as furnace oil.

These fuels emit pollutants such as sulphur dioxide, nitrogen oxides, and particulate matter, which contribute to air pollution and health issues. Shifting to cleaner-burning biofuels helps mitigate these environmental impacts and improves air quality. They produce lower carbon dioxide emissions and fewer pollutants, which helps improve air quality and reduces the contribution to global climate change.

India has set ambitious renewable energy targets to increase the share of renewable energy in its energy mix. Using biofuels instead of traditional fossil fuels aligns with these goals and contributes to the country’s efforts to reduce its carbon footprint and transition to a more sustainable energy system. Also, many parts of India face severe air pollution, leading to health issues and environmental degradation. Shifting to biofuels can help Indian manufacturers reduce their carbon footprint and comply with national and international commitments to combat climate change.

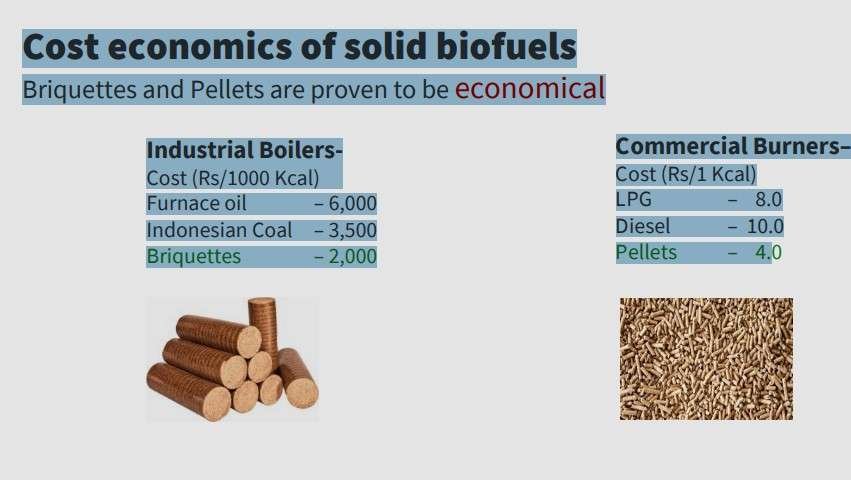

Improving economics for biofuels vs imported fossil fuels

India is heavily dependent on imported fossil fuels, which can pose energy security risks due to supply disruptions and price volatility. By promoting domestic production of biofuels, India can enhance its energy security and reduce its reliance on imported fuels. With rising prices of imported coal and furnace oil, and advancement of technology, the cost of biofuel production has become more competitive, making it economically viable for manufacturers to switch to biofuels. Advances in biofuel production technologies have made these fuels more viable and cost-effective. As technology improves, the economics of biofuel production become increasingly favorable compared to traditional fossil fuels. The Steep prices of diesel and gas makes biofuels even more attractive with over 50% cost savings.

Compressed Biogas (CBG) also presents a significant opportunity in India as a sustainable and renewable energy source, with potential benefits for waste management, rural development, and reducing greenhouse gas emissions. CBG is produced through the anaerobic digestion of organic waste materials, such as agricultural residues, food waste, and sewage sludge. CBG is a clean fuel that can be used as a substitute for compressed natural gas (CNG) in vehicles, industrial processes, and power generation. It provides an environmentally friendly alternative to conventional fossil fuels.

Augment and diversify farmer income

Biomass briquettes and pellets made from agricultural residues, crop waste, and other organic materials such as such as soya husk or mustard stalk are widely used and their usage saves 30-40 per cent vis-à-vis furnace oil, that might otherwise be discarded or burned inefficiently. By converting these materials into energy, farmers will be able to monetise the waste and improve waste management practices. Biofuel feedstocks like non-edible oil seeds and agricultural residues can provide additional income to rural and tribal communities supporting agricultural economies. Employment is generated around activities such as biomass collection, processing, and distribution which can help farmers in diversification of income as well as provide employment to rural workers.

Also, with increasing demand and as farmers earn more every year from waste, they may also look at growing energy crops such as bamboo, napier gras etc promoting sustainable land use. These renewable resources can be grown relatively quickly, making them sustainable sources of biomass for energy production. Both bamboo and Napier grass can utilize marginal or degraded lands, transforming land that might otherwise be underutilized into productive biomass sources.

Challenges in widespread adoption of biofuels

While biofuels briquettes and pellets offer many advantages as renewable and efficient forms of biofuel, there are several challenges associated with their transportation and usage that need to be addressed for widespread adoption. Briquettes and pellets have higher energy densities compared to their original biomass forms. However, their bulk density is still lower than that of traditional fossil fuels like coal. This means that more space is required for storage and transportation, leading to logistical challenges. Proper handling and storage are essential to prevent breakage and deterioration of briquettes and pellets. Special care must be taken to protect them from moisture, humidity, and physical damage during transportation and storage.

Dependence on a steady supply of biomass feedstock for briquette and pellet production can be affected by supply Chain Disruption and factors such as weather conditions, seasonal availability, and changes in agricultural practices. The availability of appropriate infrastructure, such as storage facilities and transportation networks, is also essential for efficient distribution and utilization of briquettes and pellets. Incentivization of farmers, tribal communities and other local feedstock aggregators is important to establish a seamless supply chain of biofuels. Also, ensuring consistent quality control of briquettes and pellets is important for efficient combustion and reduced emissions. Quality control measures need to be in place throughout the production and transportation processes.

A Uniform Market Access to briquette and pellet markets might also be limited in some regions, especially remote or underserved areas, making it challenging for users to obtain these biofuels. Addressing these challenges requires collaboration between biofuel producers, distributors, transportation companies, technology providers, and end-users. Improving storage and handling methods, enhancing transportation logistics, and raising awareness among users about the benefits and proper usage of briquettes and pellets can contribute to overcoming these obstacles and promoting the widespread adoption of these biofuels.

Role of technology

To mitigate many of these challenges, the most crucial value chain in the entire supply demand chain for biofuels is the efficient use of technology. Leveraging technology and creating a marketplace platform or ecosystem where various technologies related to biofuel production, processing, and utilization are showcased, traded, shared, and collaborated upon efficiently to ensure that the demand by manufacturers is met by supplying briquettes and pellets closest and fastest to help feed demand and save on transportation cost. Indian startups working in the biofuels space are actively working on this to help connect fragmented suppliers of waste to curate and supply biofuels consistently and efficiently to large fuel consumers/ manufactuers who run industrial boilers. The marketplace will serve as a hub for showcasing innovative technologies, processes, and solutions related to biofuel production, feedstock cultivation, conversion methods and distribution.

By centralizing information about biofuel availability making it easily accessible, the marketplace can accelerate the adoption of efficient and sustainable technologies across the manufacturing industry. Buyers and users of biofuel technologies can use the marketplace to evaluate different options and make informed decisions based on the features, benefits, and potential impacts. The marketplace can also serve as a platform for sharing information about regulatory requirements and policies related to biofuel technologies. Such a marketplace will contribute significantly to the growth and advancement of the biofuels industry by fostering innovation, collaboration, and knowledge sharing.

The shift towards biofuels by Indian manufacturers is a multifaceted response to environmental concerns, renewable energy goals, policy incentives, and economic considerations. This transition not only helps mitigate environmental impacts but also contributes to sustainable development and energy security.

The incorporation of the “7Rs” – rethink, redesign, repurpose, repair, remanufacture, recycle, and recover – into the manufacturing process of biofuels is a comprehensive approach to achieving waste reduction and minimizing the carbon footprint. Integrating them into the biofuel manufacturing process demonstrates a commitment to environmental stewardship, efficiency, and sustainable production practices, which are crucial in addressing waste and carbon footprint challenges.

By embracing the usage of biofuels, India can create a sustainable future by significantly reducing carbon footprint, and contribute to achieving carbon neutrality and broader net-zero targets. This shift not only aligns with environmental goals but also presents economic opportunities for rural Indian farmers and manufacturers by following principles of the circular economy through resource efficiency.