Efficient coating of brake discs – and compliance with EURO 7 regulations

The EURO 7 standard will immensely change the automotive industry: for the first time, not only emissions from combustion engines will be regulated, but also the abrasion of brakes, among other things. The initial conclusion is that the particulate matter produced by many models must be significantly reduced. As a result, OEMs and suppliers are looking for a new solution for the braking system, with coated brake discs currently proving to be the ideal solution for the task. But how can the various coating systems be applied reliably and efficiently in the context of high-volume production? EMAG offers the right answer to this question: a complete solution ready for series production for the coating of brake discs by laser deposition welding, which has already proven itself in production. But what distinguishes it in detail?

The problem is as simple as it is quickly explained. From the EU’s point of view, conventional braking systems produce too much particulate matter, with the new limit values of the EURO 7 standard leading to a very large technological “gap” between the particulate matter emissions of current and future models. The upper limit for all new vehicles is now only 7 milligrams of particulate matter per kilometer. Today, however, a car emits up to 40 milligrams, depending on the model. For manufacturers of larger models (with higher particulate emissions), this change is associated with a development task, especially as the brakes are a safety-critical component whose design is very complex in detail. The focus here is primarily on the two “friction partners” brake disc and brake pad, as their interaction generates the particulate matter.

A technical challenge

So what options are there for reducing particulate matter? This question has been on the minds of developers for some time, and extraction systems near the brakes, for example, have proven to be a problematic approach. On the one hand, only part of the emissions is extracted in this way, and on the other, manufacturers would have to plan for additional installation space and accept higher unsprung masses. The use of so-called NAO brake pads (Non-Asbestos Organic) is also not a satisfactory solution, as particulate emissions only decrease with brand-new brake discs. After a short time in use, they rise again to the current level. In this context, hard coating of brake discs is emerging as the ideal solution. The conventional brake disc is simply given a new layer that offers protection against corrosion, wear and fine dust.

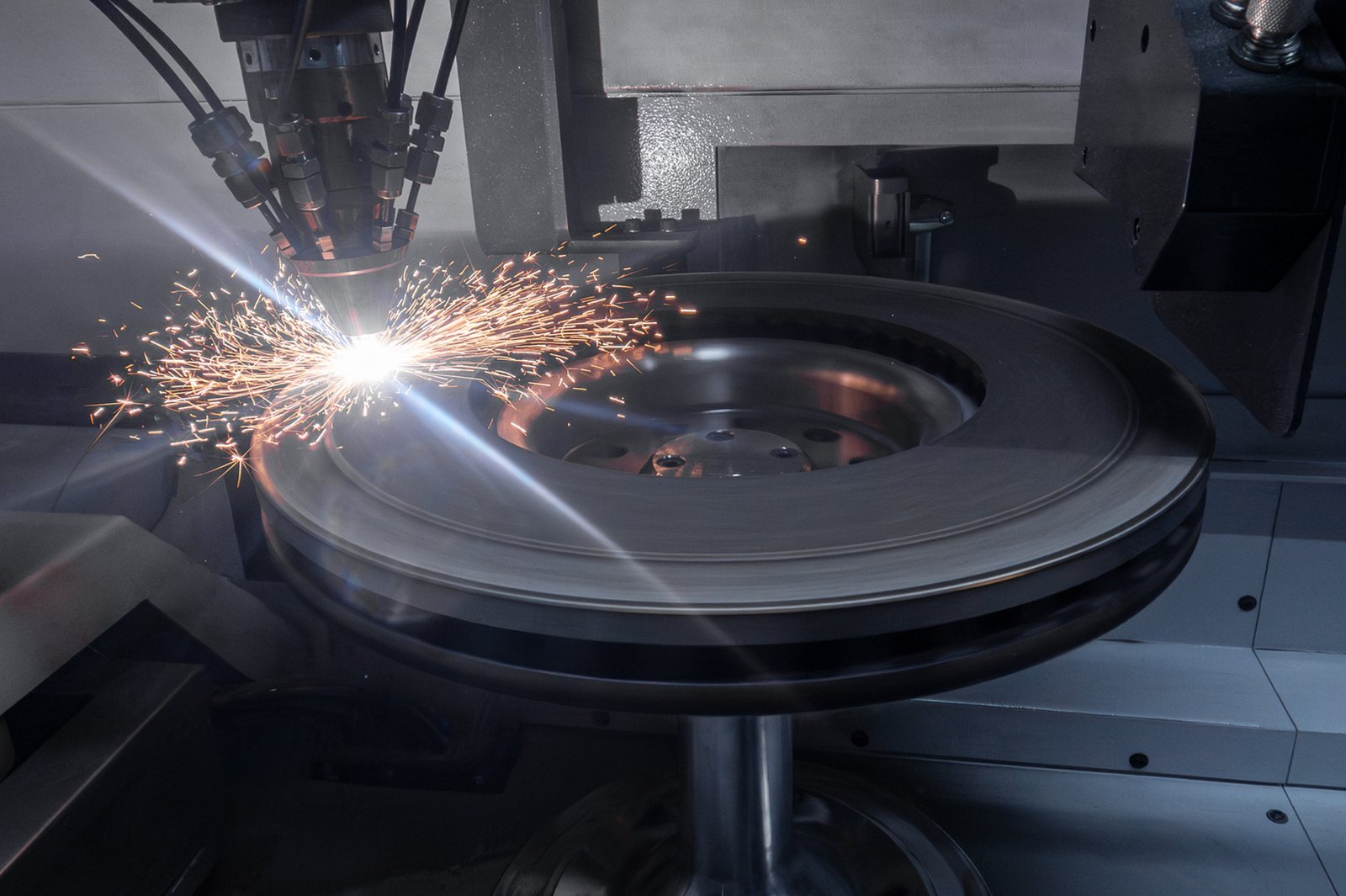

Hard coatings of brake discs are nothing new in principle, but they have so far only been used in a niche market due to high production costs. One reason for this is that thermal spraying and electroplating do not create a metallurgical bond to the base material. As a result, complex pre-processing is required to bond the coating. In addition, the layers are (too) thick and the heat input is high. In this context, a new development from EMAG in the field of laser cladding of brake discs represents a quantum leap for this task. The new production solution is economical, suitable for large-scale production, reliable and variable, as a variety of material combinations can be used for coating.

ELC 450 LMD – modular machine solution for laser metal deposition

The ELC 450 LMD is an innovative machine solution from EMAG that is characterized by its modularity and flexibility. The basic idea behind the ELC 450 LMD is the use of process modules that can be combined and expanded according to customer requirements. The machine is available in various configurations depending on the number of process modules. The basic version, the ELC 450 LMD, has one process module. The ELC 450 DUO LMD is equipped with two process modules, while the ELC 450 TRIO LMD, as the name suggests, uses three process modules. These modular machine concepts make it possible to optimally meet customer requirements in terms of shift structure and productivity. This then determines the choice of machine configuration. The ELC 450 LMD can realize both 1-shift and 2-shift systems. The combination of laser power and application rate determines the most suitable machine concept for the respective application.

The longer service life of coated brake discs also has a positive effect and helps to reduce the environmental impact. In contrast to conventional brake discs, coated brake discs have a significantly longer service life, which means that they need to be replaced less often. This reduces the need for new brake discs and helps to reduce the environmental impact of their manufacture, transportation and disposal. In addition, the new generation of brake discs reduces vehicle maintenance, saving time and money. Overall, the coating of brake discs offers a sustainable solution for extending the service life of brake discs and reducing the environmental impact.