As India rapidly embraces Industry 4.0, automation and robotics are no longer optional; they are essential tools for increasing productivity, ensuring consistent quality, and staying competitive in global markets. Whether in automotive plants, electronics assembly lines, logistics warehouses, or food processing units, robots are transforming how materials are handled, assembled, and packed. But the performance of these robots depends not only on their speed or programming, it hinges on how reliably they can pick, hold, and place parts. This is where gripping systems, especially vacuum-based solutions, play a defining role.

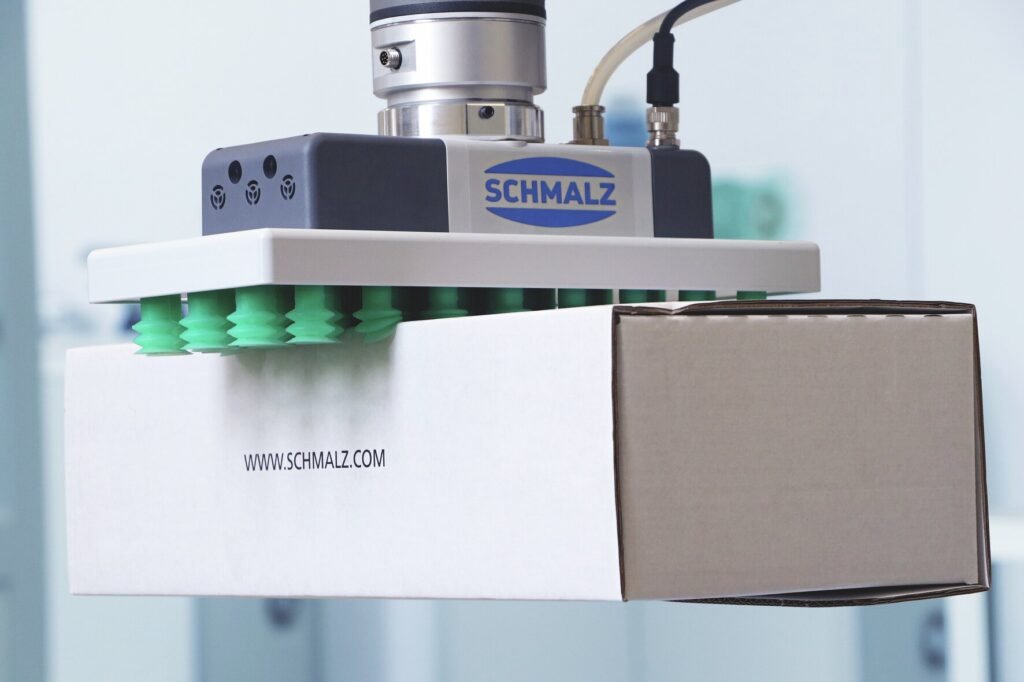

The gripper is the robot’s physical link to the workpiece. It determines how safely a carton, a metal plate, or a glass vial is picked without damage. It affects cycle time, placement accuracy, and whether a robot can switch quickly between different parts or products. A poorly chosen gripper can cause slippage, misalignment, or even production stoppages. That’s why Schmalz, a global leader in vacuum automation, is at the forefront of developing smart, adaptive, and efficient gripping systems for a wide range of manufacturing tasks. Their solutions are not just tools—they are enablers of seamless automation, tailored to meet the growing diversity of Indian manufacturing industries.

In high-speed material flow applications like palletising and de-palletising, common in logistics, automotive, or food & beverage sectors, Schmalz offers the Vacuum Layer Gripper SPZ, engineered to lift entire layers of cartons, cans, or bags quickly and securely. What makes the SPZ unique is its large-area vacuum contact and ability to gently yet firmly grip even slightly uneven surfaces without damaging packaging. For production environments that require picking and placing varied or fragile items, like electronics boards, glass packaging, or delicate consumer goods, the FQE Area Gripper delivers reliable performance with maximum flexibility. Its broad sealing surface conforms to different product shapes, while the integrated ejectors ensure fast gripping and release cycles. The FQE is also highly compact and lightweight, which allows faster robot movements and energy-efficient operation. Importantly, its smooth contours and safety-compliant design make it suitable for collaborative use, such as in shared workspaces between humans and robots in light assembly or quality inspection cells.

For dedicated collaborative robotics (cobot) applications, Schmalz has developed the FXCB and FMCB series, specially designed to work alongside people. These grippers combine a safe, rounded design with smart functionality, like built-in vacuum generation, lightweight construction from 3D-printed materials, and plug-and-play integration using standard robot flanges. Whether in automotive kitting, pharmaceutical packaging, or food-grade environments, these grippers enable robots to perform repetitive or ergonomic tasks safely while maximising their payload and reach. Their simplicity in setup and quick changeovers allow manufacturers to deploy cobots flexibly, without needing in-depth programming or custom hardware each time a new product is introduced.

For automation tasks involving flat, sealed workpieces, the Vacuum Area Gripping System FEL offers a lightweight and cost-effective solution. Designed for efficient handling of uniform surfaces, the FEL is ideal for picking items such as delicate electronic componentslike laptop, tablet, mobile, small display screens and flat-glass elements. Its compact design integrates vacuum generation directly within the unit, eliminating the need for external ejectors and simplifying installation, especially in space-constrained robotic arms or gantry systems. The gripper’s rigid housing and replaceable foam sealing pad ensure consistent suction and reliable surface contact without damaging sensitive parts. As a result, the FEL is being used in industries ranging from electronics assembly and packaging to intralogistics and light industrial automation, where ease of integration, cycle-time stability, and part safety are critical.

Meanwhile, the SLG Lightweight Gripper is ideal for customised handling of small components using cobots or compact robotic arms. Thanks to additive manufacturing, the SLG can be tailor-made to match the shape, spacing, and handling needs of the specific parts being moved. This makes it particularly suitable for electronics, plastics, cosmetics, and consumer goods industries, where product shapes vary frequently. Despite being extremely lightweight, the SLG delivers a reliable holding force and supports high dynamic movements. Its modular, ready-to-connect design speeds up integration, allowing automation experts to quickly deploy and redeploy it across different workstations without sacrificing performance or precision.

What ties all these gripping systems together is the tangible benefit they offer to Indian manufacturers. With Schmalz grippers, users see faster cycle times, fewer product defects and increased throughput, whether handling 50-gram vials or 50-kg component layers. Their modular and lightweight designs mean easier integration into existing lines, while the robust construction ensures long service life and minimal downtime. More importantly, these systems reduce physical strain on human operators by automating repetitive, heavy, or awkward manual handling tasks, supporting a safer and more productive shop floor.

In a market that demands speed, agility, and reliability, Schmalz gripping systems are enabling the next generation of Indian automation, built on smarter gripping, not just smarter robots.

Courtesy: Schmalz India