Kennametal India Limited will showcase its comprehensive portfolio of high-performance wear-resistant solutions tailored for the downstream sector of oil and gas operations at the Refinery & Petrochemical Technology Forum (RPTF) 2025, taking place 19–20 August at Hotel Crowne Plaza, Mayur Vihar, New Delhi, India.

At the event, visitors to the Kennametal booth will discover a wide range of engineered solutions designed to extend the life of mission-critical components in high-wear environments. The portfolio includes:

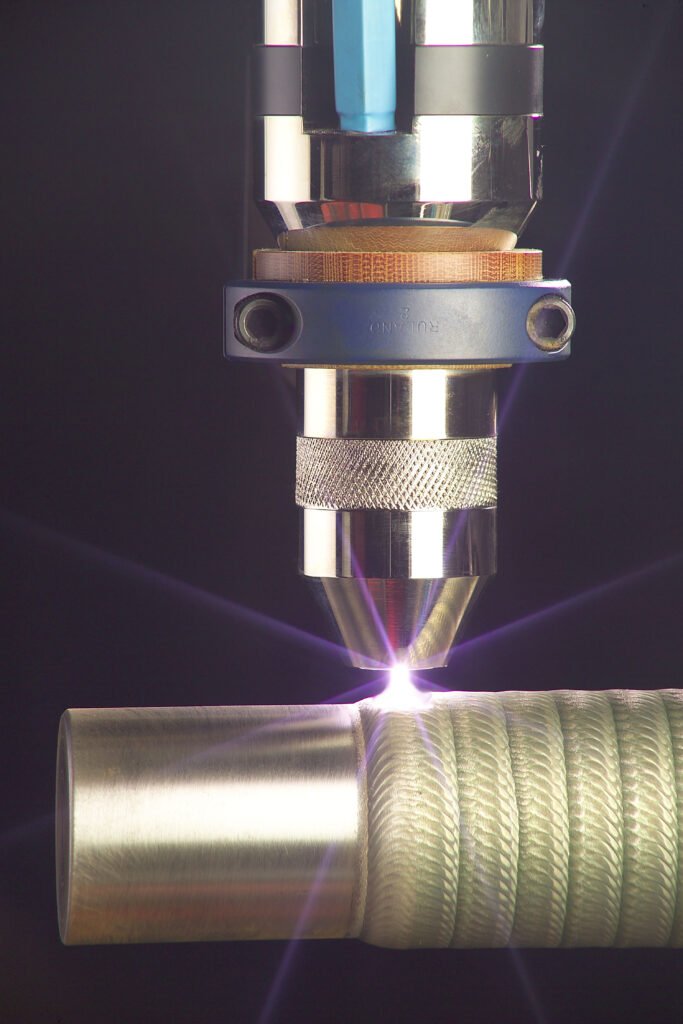

- Conforma Clad, Dies & Wear Parts, Welding and Hardfacing Consumables, and the Stellite™ product line

- Cladded components such as Radial Return Bends, Conveyance Bends, Pumps, and Thermowells

- Thermal Spray & Hardfacing Powders, Cored Welding Wires, Welding Rods/Electrodes

- Solid Tungsten Carbide Products including Cages, Plugs, Wear Liners, Diffusers, Baffles, Chokes, Seats and Cage Assemblies

These engineered coatings, applied as cladding to customer-supplied components, along with advanced tungsten carbide systems, offer proven protection against erosion, abrasion, corrosion and extreme temperatures. The result: extended service life, reduced downtime and optimized lifecycle costs.

“India’s refining and petrochemical sectors are evolving rapidly, bringing with them increasingly complex wear and corrosion challenges,” said MT Swamy, Director of Sales at Kennametal. “At Kennametal, we engineer solutions with durability at the core – whether it’s precision die plates for polymer production or cladded components designed to perform in cokers, gasifiers and VCM units. Our technologies are built to deliver reliability where failure is simply not an option.”

Kennametal’s solutions are trusted by OEMs and operators worldwide for both standard and severe service applications, helping protect mission-critical assets and drive operational efficiency.

For more information or to schedule a meeting with Kennametal experts at RPTF 2025, please visit – https://www.kennametal.com/in/en/home.html