Integrated automation controller with built-in CC-Link IE TSN Ethernet, delivers seamless data connectivity, advanced engineering support, and high-speed, high-precision, multi-axis motion control.

Mitsubishi Electric has introduced the MELSEC MX Controller, an all-in-one solution engineered for high-speed, high-precision applications. It combines sequence and motion control, while also integrating an OPC UA server and CC-Link IE TSN network to enhance data visibility and connectivity. Built-in cybersecurity features and enhanced no-code programming support make it a key enabler of digital transformation (DX) in manufacturing.

The controller also meets the increasing demand for multi-axis control in fast-growing industries such as lithium-ion battery (LiB), semiconductor, and LCD manufacturing, delivering high-speed control of 128 axes in just 1.2ms and multi-axis control for up to 256 axes.

The MELSEC MX Controller offers full CC-Link IE TSN compatibility across all models, enabling high-speed, synchronised communication. Combined with a software-based architecture running on a high-performance multi-core MPU, it delivers up to 10 times the motion control performance of previous models*1 and ensures stable operation across multiple axes, even with differing control requirements.

To further boost productivity and reduce engineering workloads, the controller supports intuitive, one-tool development, AI-based debugging and analysis, and compliance with international programming standards. Variants tailored for motion control in food and packaging, EV manufacturing, and electronics production are also available*2, offering users the flexibility to build efficient, responsive systems.

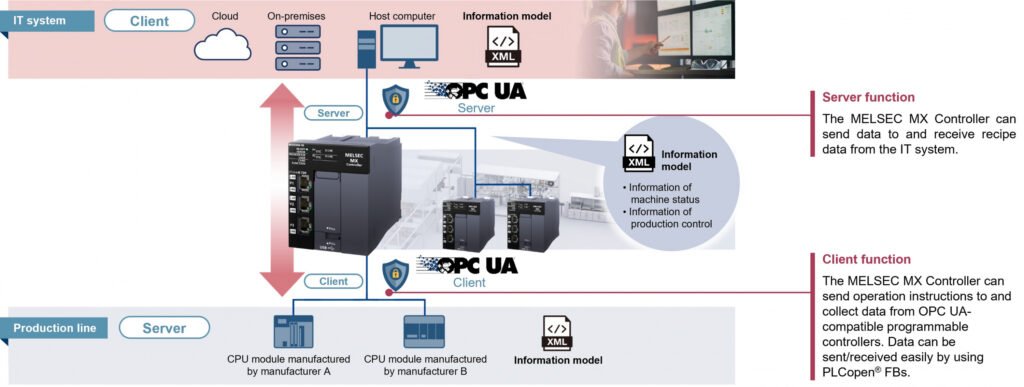

With cybersecurity now a growing concern for the manufacturing sector, Mitsubishi Electric is also pursuing IEC62443-4-2 certification — a key international security standard for control systems. The MELSEC MX Controller also features an OPC UA server, with client capabilities*3 planned for future updates. This enables secure data exchange across multi-vendor environments and helps to drive digital transformation (DX) in modern factories.

Key Features

1. High-speed, high-precision, multi-axis motion control with built-in CC-Link IE TSN

Powered by a high-performance multi-core MPU and software-based architecture, the MELSEC MX Controller delivers up to 10x improvement in motion control performance over previous models. One controller supports up to 256 axes, including high-speed 1.2ms control of 128 axes.

With integrated CC-Link IE TSN, the controller optimizes communication cycles and supports three simultaneous control cycles within the same unit (2ms, 500µs, and 125µs). This enables precise tuning of individual axes — ideal for applications like winders or coaters where varying speeds must be maintained without compromising performance or stability.

2. Streamlined engineering with AI support.

The MELSEC MX Controller simplifies development with “no-code” programming via Function Blocks (FBs) compliant with international PLC open Motion Control standards, helping reduce both design time and development costs.

Using the MELSOFT GX Works3 engineering tool, users can perform sequence and motion programming in a unified environment — significantly accelerating project timelines. Additional AI-powered features include data flow analysis, real-time program visualization, watch windows, and advanced debugging tools to help engineers quickly pinpoint and resolve issues.

3. Advanced cybersecurity for industrial environments

With the increased focus on cyber security for manufacturing systems, the MELSEC MX Controller is designed to meet IEC62443-4-2 standards*4. It features secure OPC UA server support*5, providing encrypted OT communication across platforms and ensuring protection from unauthorized access and data breaches.

Security features include:

- Encrypted communication and user authentication

- Role-based access control for both end users and equipment

- manufacturers

- Startup integrity checks to detect and block tampered programs

4. Enabling digital transformation (DX) through digital twins

The controller is compatible with ‘digital twin’ technologies such as MELSOFT Gemini and MELSOFT Mirror, allowing users to simulate entire systems before deployment. This minimises on-site commissioning time and supports faster, more reliable troubleshooting.

Additional features include automatic logging during abnormalities, enabling rapid root cause identification through analysis tools without halting production.

The MELSEC MX Controller also supports the reuse of existing MELSEC iQ-R/iQ-F series assets such as base units, power supplies, and modules*6, offering added flexibility and investment protection.

Model Lineup

Future Roadmap

Mitsubishi Electric will continue to expand the MELSEC MX Controller’s capabilities, with planned updates including advanced network features, enhanced maintenance functions, and broader system integration.

Ongoing progress toward IEC62443-4-2 compliance, together with enhanced DX compatibility through deeper integration with simulation tools, will further support manufacturers in optimizing design, performance, and operational efficiency within a rapidly evolving industrial landscape.

*1 Compared to previous Mitsubishi Electric models.

*2 Axis capacity: MXR500 – 256 axes; MXR300 – 64 axes; MXF100 – 16 axes.

*3 OPC UA client functionality and information model to be supported in future updates.

*4 Initial support for MX-R models; future expansion planned for MX-F models.

*5 OPC UA client and information model support coming in future updates.

*6 Compatibility may vary for certain modules.

*7 □ will be replaced with either N (transistor output [sink type]) or P (transistor output [source type]).