STUDER has further developed the globally successful CNC universal cylindrical grinding machine favoritCNC, incorporating years of grinding and mechanical engineering experience. The result is modern grinding technology with high precision and simple operation for a very good price-performance ratio.

“With numerous new features, optimizations, and automation capabilities, the favoritCNC is a future-oriented, economical solution for the external and internal cylindrical grinding of small to medium-sized workpieces in individual and series production. Both for high-quality contract manufacturing and in-house production,” says Sandro Bottazzo, CSO at STUDER. The Swiss quality manufacturer of cylindrical grinding machines has further developed the proven entry-level machine, drawing on its many years of experience. Manufacturing companies now have a modern CNC universal cylindrical grinding machine whose advantages include high accuracy, short machining times, and intuitive operation for a cost-effective investment

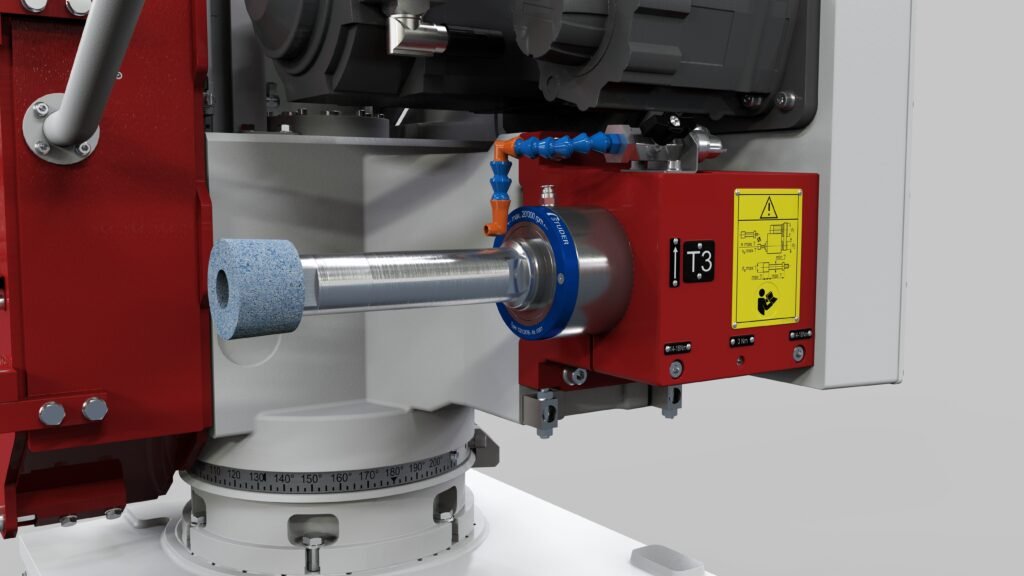

The latest generation of the favoritCNC features a modernized CNC control (FANUC 0i-TFP), software, and smart automation capabilities. Thanks to the new automatic operating door and loader interface, customers can now automate their production themselves. Further optimizations have been made regarding its operation with a view to sustainability and efficiency, and in ergonomics for even easier and safer operation. For example, user-friendliness is significantly increased by the simple grinding wheel changing aid and park position for the tailstock within the machine (optional). The new features also include the machine base with a larger distance between the X-guideways for even greater wheelhead stability, a resource-saving belt spindle system, the digital display of the swivel angle on the manual B axis, and the optional QuickSet function for exceptionally fast retooling.

Flexible Application Options and High-quality Components

When defining the equipment on the new favoritCNC, STUDER focused on flexibility, which is particularly important for customers in this segment. There are two wheelhead variants to choose from: a fixed wheelhead for productive external grinding (manual positioning 0° / 15° / 30°) or a universal wheelhead for external and internal grinding (grinding in one clamping, manual swivel 2.5° Hirth coupling). There are also numerous configuration options, such as a fixed or swiveling worktable, or options such as measuring and balancing systems, grinding detection, and longitudinal positioning. This means the machine can also be subsequently retrofitted for different grinding tasks and production conditions.

With the favoritCNC, customers benefit from an optimal interplay of hardware and software and STUDER’s expertise as a quality manufacturer of innovative cylindrical grinding machines with a history stretching back 112 years. As a result, the machine contains high-quality components and modern and reliable grinding technology. For example, the workhead, grinding spindles, guideways, and drives meet the high-performance standards of STUDER’s premium segment. The machine bed made from the company’s own Granitan® S103 mineral casting with its outstanding damping and thermal properties also ensures excellent surface quality on the favoritCNC.

Simple Operation and Smart Software

The operation of the new favoritCNC is now even easier and user-friendly via a 10.4-inch flat screen and an ergonomic manual control unit close to the grinding process. In addition, the internally developed and optimized StuderPictogramming and StuderGRIND grinding software provide modern digital solutions that allow even complex grinding processes to be set up and controlled intuitively. On the new favoritCNC, it is now possible to grind non-circular forms and threads with StuderThread and StuderForm. Thanks to the machine’s digital capabilities, even employees with little knowledge of CNC grinding can quickly achieve high-quality results.

With the new conventional grinding mode, the machine is also capable of manual grinding. This allows users to efficiently produce high-quality ground workpieces without programming knowledge, making the switch from a conventional machine to a CNC particularly easy. “As a result, the new favoritCNC is an optimal solution for a wide range of different grinding applications,” summarizes CSO Bottazzo.

The favoritCNC at a Glance

- Distance between centers 650 mm / 1000 mm (25.6”/39.4”)

- Center height 175 mm (6.9“)

- Max. Workpiece weight 80 / 120 kg (176/264 lbs)

- Grinding wheel diameter max. 500mm (20”)

- Short processing time thanks to complete machining (in one clamping)

- Maximum precision thanks to perfect interaction between hardware and software

- Intuitive, user-friendly, and efficient operation

- Ergonomic thanks to good accessibility to the grinding area

- Ecological thanks to targeted measures for lower energy consumption and sustainable use

Hardware:

- Wheelhead can be used for external and internal grinding (machining in one clamping)

- Two variants to choose from: Fixed wheelhead with manual positioning (0° / 15° / 30°) or optional universal wheelhead with grinding wheel on the right and internal grinding (option) with manual swiveling 2.5° Hirth

- Fixed table or swiveling table (up to max. 8.5°)

- Granitan® S103 mineral cast machine base

- Fanuc F0i-TFP machine control system

- Digital display of the swivel angle

- Modern measuring system and sensor technology

- Automatic door

- Ergonomic manual control unit for setting up close to the grinding process

Software:

- Simple programming thanks to StuderPictogramming

- StuderGRIND programming software (optional) for creating grinding and dressing programs on an external PC

- New StuderForm (optional)

- New StuderThread (optional)